30′ x 40′ x 14′ Steel Building Sale

View Wholesale Steel Building Prices and buy at an average of 10% below market rates.

Steel building Wholesale Prices with listed profit amount

STANDARD 1:12 – 30′ x 40′ x 14′

Key Features

- 1:12 Roof Pitch

- 30 Galvalume Plus Roof Finish Warranty

Codes: 4 lbs. roof load, 110 mph wind Speed, Exposure B. We quote sizes 30’x 40′ x 10′ to 100′ x 500′ x 26′. Codes 0 – 100 lbs roof load, 85 to 170 mph wind speed, Exposure B, IBC2018

Steps To Saving On Steel Building Prices

- Fill out one of these forms: Name Your Price or Wholesale Steel Building Quote,

- Call 1-888-512-1116 to to inform the representative that a form was submitted.

- After the quoted savings, pay the low $1,000 service fee that SAME DAY.

- Pay a 30% deposit to the certified manufacturer within 7 days. For more information, click Order to Delivery.

- Buildings are delivered in 8-9 weeks.

Standard I-Beam Steel Building Specifications

Free (Initial) Certified Building Plans for ALL 50 states.

- Letter of Certification

- 2 sets of certified stamped anchor bolt plans

PRIMARY FRAMING

(Mainframes)

SOLID I-BEAM CONSTRUCTION Material used is 34,000 and 55,000 p.s.i. yield strength. (Some manufacturers use only 34,000 p.s.i. yield strength material). Frames are single bead, continuous submerged arc welded by automatic welding machines to help ensure quality. A factory-applied rust inhibiting primer is used to help protect the mainframes and secondary material during the erection process.

ENDWALL FRAMES AND COLUMNS are either cold formed, hot-rolled or built-up “I” sections depending on design requirements.

SECONDARY FRAMING

GIRTS (in sidewall) and PURLINS (in roof) are minimum 8” to meet design requirements. Cold rolled Z-section, 12 to 16 ga ASTM A-653, 55,000 p.s.i. yield material is used to provide maximum strength.

Bypass girt system overlaps at sidewall columns forming a continuous “span” for extra strength. All girt clips are factory welded for easier erection.

PURLINS are top-mounted on the rafter with a varied lap of 1’6” to 5’ for strength and cost savings in erection labor. Maximum purlin spacing is 5’ on center.

EAVE STRUT is a cold-formed C-section that is rolled for the appropriate roof pitch to help insure weather tightness at the eave.

RAKE ANGLE is a 2×4 angle supplied for the attachment of the sheeting at the rake of the building for ease of installation.

BASE ANGLE is a 2×4 angle supplied for the attachment of the base of the sheeting to the concrete. The base angle is to be attached to the concrete with ram-sets or equivalent anchors.

BRACING All diagonal galvanized cable bracing is supplied for roof and walls to remove longitudinal load from the structure. Galvanized cable is used rather than solid rod to prevent the bracing from “sagging” under its own weight and it is easier to install. All cables are pre-stressed and pre made for easier erection.

Angle Flange Bracing is provided for the connection of the rigid frame to the purlins and girts. This ensures the allowable compressions are adequate for any combination of loading.

FRAMED OPENINGS have cold-formed C-section jambs and headers to help insure easy installation of overhead doors, etc.

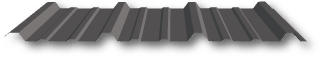

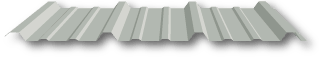

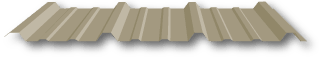

SHEETING

26 gage 80,000 P.S.I. yield strength material standard. Some manufacturers use a lower yield strength material, which is less resistant to damage from hail or other impacts.

ALL COIL STEEL has a minimum of G-90 class Galvalume substrate (1.25oz hot dipped) to help prevent deterioration of the steel sheeting.

DEEPER HIGH-RIB with more frequent corrugations provides extra strength.

OPTIONAL ARCHITECTURAL PANEL configuration is available for walls, mansard systems, soffit material, etc., to add an aesthetic appeal to your building.

FASTENERS

STRUCTURAL BOLTS meet requirements ASTM Standards. A-325 for primary frame connections A-307 for secondary framing

SELF-DRILLING AND SELF-TAPPING FASTENERS are pre-assembled with neoprene washers and metal caps to help insure weather tightness.

CLOSURES

CLOSED CELL NEOPRENE STRIPS are used to help seal building. Located at eave, gable, and optional at the base of building to help provide weather tightness. Pre-formed shapes to match panel configuration providing a tighter seal.

1-1/2” SHEETING NOTCH at base of concrete where panel site is designed into every building. Sheeting notch provides an air infiltration stop on blanket insulated building.

SEALANTS

SEALANT for roof sidelaps, endlaps and flashing at gable is provided to help insure weather tightness. Nominal 3/8” x 1/8” thick pressure sensitive tape sealant for ease of installation.

RIDGE CAP

LONG OVERLAP to help prevent water from siphoning into building.

TRIM AND FLASHING

All buildings are fully trimmed at rake (gable), corners, and eaves with standard trim material for a more finished look. This not only improves look of building, it is an additional deterrent to moisture, insects, and dirt from getting into the building.

PLANS AND DRAWINGS

ANCHOR BOLT setting plan, building reactions for foundation design, Erection Manual, and Engineer Letter of Certification is provided shortly after receipt of deposit for building.

ERECTION DRAWINGS provide step-by-step instructions for the case of assembly by dealer or customer.

ENGINEER CERTIFIED APPROVAL DRAWINGS including wall and roof framing diagrams, cross sections, sheeting, and flashing details are provided. These drawings clearly show the proper erection and assembly of all building components.

ALL PARTS ARE NUMBERED Part number is placed on each component (not including sheeting, screws, etc.). These part numbers coincide with a detailed listing contained in the bill of materials that comes with your building. The same numbers are also used on the drawings for clarity and to help with assembly on the job site.

For more details, click Specifications

Metal Building Colors, Trim Colors, and Roll Up Door Colors

You will list your colors on the Predesign Building Quote-Order Form.

The building colors have a 40-year warranty. Galvalume Plus color has a 30-year warranty.

***Roll Up Door colors are posted below WALL and TRIM color swatches.***

ROLL UP DOORS