Fiberglass Insulation

Vinyl-Faced Fiberglass Insulation | White Vinyl-Faced Insulation

Finally, a Cost-Plus Buying Program for Vinyl-Faced Fiberglass Insulation with no hidden costs that yields TRUE SAVINGS!

Steps to Buy at Cost-Plus:

- The general public uses the Fiberglass Insulation Wholesale Calculator (below) to determine wholesale cost for FREE!

- To order, complete an order form and pay the associated profit to Factory Steel Overstock (FSO).

- Customers then receive an order # and easy instructions for paying the wholesale cost directly to our certified supplier.

- The shipping department calls to schedule a convenient delivery date. Expedited shipping is 3-10 days. Standard shipping is 11-21 days.

Need To Determine Your Building’s Square Footage?

WMP Facing Options Explained (VR-R, WMP-10, WMP-30, WMP-50)

Review the features of each WMP Facing Options. Then, click the preferred Buy Now button:

WMP-VR-R + Entry-Level Vapor Retarder

Normal Strength

PSP-Polypropylene /Scrim/Polyester

Perm – 0.02

MD tensile lbs/inch – 35, XD – 35

Mullen Burst PSI – 100

Fire Performance: UL-723, ASTM E84, Factory Mutual, Class A-1

Featuring a tri-directional scrim.

The metalized polyester back reflects some radiant heat away from the structure.

This WMP-VR-R (plus) Reinforced Vinyl-faced Fiberglass Insulation facing is easier to roll, cut, and install for DIY projects.

Most popular option!

WMP-10 Light-Duty Metal Building Insulation Facing

Enhanced Strength

PSK-STD –Polypropylene/Scrim/Kraft

Perm 0.02

MD tensile lbs/inch – 40, XD – 35

Mullen Burst PSI – 65

Fire Performance: UL-723, ASTM E84, CAN ULC-S102M, Factory Mutual, BS 476 Class 0, Class A-1

The Kraft side of WMP-10 & 30 reinforced vinyl-faced insulation may wrinkle less noticeably or recover more nicely over time than the metallized polyester of the WMP-VR (plus) and WMP-50.

WMP-30 – Most Popular Contractor-Grade Facing

Industrial Strength

PSK-HD Polypropylene/Scrim/Kraft Heavy Duty

MD tensile lbs/inch – 55, XD – 40

Mullen Burst PSI – 70

Fire Performance: UL-723, ASTM E84, CAN ULC-S102M, Factory Mutual, Class A-1

WMP-30 facing is often selected when the insulation may be exposed to additional wear and tear.

The WMP-30 reinforced vinyl-faced insulation is thicker and stiffer than the WMP-10; therefore, in tight or complex installations, it can be harder to work with.

WMP-50 – Heavy-Duty Scrim-Reinforced Facing for Warehouses

SALE!

Premium Strength

PSKP Polypropylene/Scrim/Kraft/Polyester

Perm – 0.02

MD tensile lbs/inch – 65, XD – 60

Mullen Burst PSI – 120

Fire Performance: UL-723, ASTM E84, CAN ULC-S102M, Factory Mutual, BS 476 Class 0, Class A-1

The WMP-50 Reinforced Vinyl-faced Fiberglass Insulation is the ideal choice for high-abuse areas that require extra durability.

The metalized polyester back reflects radiant heat away from the structure.

Vapor Barrier Protection Chart

| Facing | Breathability | Vapor Control | Typical Use |

|---|---|---|---|

| WMP-10 | High | Low | Dry climates – low humidity |

| WMP-30 | Medium | Medium | Light-to-moderate humidity, mixed climates |

| WMP-50 | Low | High | Cold climates – moderate humidity |

| WMP-VR / VR Plus (Most popular) | Very low | Very high | High humidity |

Black-Faced Fiberglass Insulation for Open Structures

Fiberglass vinyl-faced black insulation, with a matted look, offers reliable thermal performance, moisture resistance, and a clean, durable vapor barrier—ideal for pole buildings, metal buildings, and warehouses seeking efficiency and longevity.

Fiberglass Insulation Thickness vs R-Value

| R-Value | Approx. Thickness (inches) |

| R-8 | 2.5 to 2.75″ |

| R-10 | 3.0″ |

| R-11 | 3.3 to 3.5″ |

| R-13 | 4.0″ |

| R-19 | 6.0″ |

| R-25 | 7.8 to 8″ |

| R-30 | 9.25 to 9.5.” |

Who Is Factory Steel Overstock?

It is an independent broker that has secured the lowest wholesale rates in the industry! Factory Steel Overstock specializes in black-and-white vinyl-faced insulation and I-beam metal buildings, serving the continental United States. It was founded by a 40-year industry veteran, a practicing Spiritual Practitioner, committed to pricing transparency. Its mission is to level the playing field between corporations and the general public by empowering consumers with real costs.

It has shipped millions of square feet of insulation from 24 strategically located certified fiberglass laminators that hold NIAMA, NIA, and ASTM certifications. It ships metal buildings from 12 strategically located certified building fabricators that hold IAS (International Accreditation Service) certification. Contractors and the public can expect low shipping rates and quick delivery timelines.

Factory Steel Overstock was established in 2011 and maintains an A+ Better Business Bureau grade and all 5-star reviews.

Why Contractors and the Public Buy From Factory Steel Overstock

Transparent Cost-Plus Pricing

Everyone wants the lowest possible prices without compromising on quality. With Factory Steel Overstock’s transparent cost-plus pricing, you get exactly that!

Contractors and the public see the real cost – before added profits – and predetermined profit amounts upfront. They no longer have to buy from traditional commission-based salespeople who often over-inflate margins for their own benefit. They can utilize FSO’s buying leverage, expertise, and specialized knowledge to secure savings. In an era when deceptive sales tactics are common, FSO stands apart with a no-gimmicks, no-hidden-cost philosophy—where customers never overpay.

Factory Steel Overstock has a simple selling philosophy: reduce its operational cost, and these savings will be passed down to you. Everyone wants savings; however, not everyone is willing to earn them. Most people’s selling practices are retail-oriented; they call to request a quote without knowing when, or even if, they will purchase, regardless of the price they receive. There is nothing inherently wrong with this behavior; however, it will always yield a retail price. How can it not? It offers the seller nothing in return! You can help us by clearly letting us know what you want. Then, be willing to pay us the corresponding profit once we present a reduced market price.

💰Wholesale Cost-Plus Insulation Pricing Model💰

OPTION 1: Orders below $3,000

$395 FEE

OPTION 2: Orders $3,001 – $10,000

$675 FEE

OPTION 3: Orders $10,001 – $30,000

$1,075 FEE

OPTION 4: The FEE will be reduced or waived if you locate a lower market quote.

Why Does All of FSO’s New Business Come from Repeat Customers, Referrals, and Organic Searches — Instead of Advertising?

The public sees the actual wholesale price and profits. There are no hidden costs!

You pay FSO a clearly posted service fee— the profit — nothing more!

You pay the certified supplier the clearly listed wholesale cost + applicable taxes – nothing more!

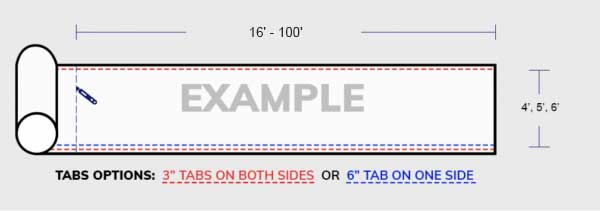

Standard Insulation Roll Sizes

Widths: 4′, 5′, and 6′.

Length: 16′-100′

Tabs: 2-3″ or request 1-6″.

Custom Insulation Roll Sizes

8’ wide facing is available! It is offered only with WMP-30, which is 101”. This would result in (2) 2.5” tabs.

The narrowest facing is 42”, which is typically used for 36” fiberglass, which would give you (2) 3” tabs (one each side) or (1) 6” tab (one 6” and the other side has facing/insulation with no tab).

So, if 24” fiberglass is desired, you would have (2) 9” tabs, due to the use of 42” facing. If someone wants 36” fiberglass…the same 42” facing would be used, but it would result in (2) 3” tabs.

A cut charge applies to 24” and 36” fiberglass. For budgetary purposes, charging the 24” at the 36” price should cover the cost. Same with 36” at the 48” price.

A cut charge applies to length cuts under 16′. For budgetary purposes, approximately $0.4 per ft.

Tape, Banding, and Installation Accessories

Tape, banding, and screws will match the color of the chosen insulation facing. List desired items on the order form.

Double-Sided Tape

$35

3″ x 150′. Recommended one roll per 2,000 square feet.

Double-sided tape is usually applied before installing sheeting. It temporarily holds the insulation in place until the sheeting is installed.

Patch Tape

$35 ($25 for same-day call as order).

1/2″ x 60′. Recommended one roll per 15,000 to patch. If sealing around doors, windows etc., order additional rolls.

Used to repair tears, seal gaps, joints, and seams, ensuring a continuous thermal barrier.

Insul-Holds

$78

100′ in length

These hangers will keep the heavier vinyl-faced insulation R-values from sagging in the cavity over time.

Has hooks (arrow prongs) spaced every 8″ inches on center.

Banding

$175

One roll of 500′ banding per 1,000 square foot of coverage.

This is usually bought when installing vinyl-faced insulation in a retrofit project. It helps prevent the insulation from sagging and shifting.

Fiberglass vs Spray Foam vs Reflective Insulation

All insulation types have their market niche, as well as pros and cons. Factory Steel Overstock could offer every insulation type; however, it to offers what the most cost-effective insulation for metal buildings and pole barns, which in fiberglass vinyl faced insulation.

Fiberglass Vinyl faced Insulation vs Spray Foam

COST:

One of the most expensive insulation options on the market is Spray foam. Unlike fiberglass, which is a popular DIY material due to its ease of installation, spray foam is far more labor-intensive and usually requires professional application. With a metal building, a layman simply rolls the vinyl-faced insulation over the purlins and girts, then pins it down while installing the sheeting material. Although Spray Foam may offer a higher per square foot thermal efficiency than fiberglass viny faced, one has to consider the additional initial investment required.

HEALTH FACTORS:

One must also consider that the chemicals used in spray foam can release toxic gases if not installed properly. That is not an issue with fiberglass vinyl-faced insulation. It is imperative that one verifies that the space being insulated is well-ventilated and that all safety measures are implemented during installation.

EXPANSION:

Fiberglass Vinyl-faced insulation is not going to expand; however, the nature of spray foam is to expand as it cures. This can sometimes lead to unwanted pressure on drywall and framing if not closely watched during installation.

Fiberglass Vinyl-faced Insulation vs Reflective

Effectiveness in Cold Climates

Reflective insulation is designed to reflect radiant heat away from your metal building or pole barn; therefore, it is an ideal insulation type in hot climates. Its primary purpose is to keep your structure cool; however, most locations require insulation to address climate conditions for all seasons. In other words, an insulation that also deals with winter temperatures. Reflective insulation has a limited ability to resist heat flow, which makes it less effective in cold climates. For this reason, fiberglass vinyl-faced insulation is a more practical choice.

Airspace Installation Requirements

Simply put, reflective insulation requires a gap to be effective, and there are situations where this may be a challenge during installation. This is not a requirement with Fiberglass Vinyl-faced insulation.

Although all insulation types have their market niche, pros and cons, fiberglass vinyl-faced insulation is the most preferred type for DIY projects. Ready buyers, call 1-888-512-1116.

I-Beam Metal Buildings

Why Metal Building Buyers Pay More for INSULATION After the Initial Order

Traditional metal building sellers often encourage customers to purchase a bare-bones building package first, postponing accessories—especially insulation—until after the building deposit is secured. While this approach may seem convenient at the time, many buyers quickly discover it leads to significantly higher INSULATION costs later in the process.

The Common 2 Step Sales Sequence

Step 1: The “Lock in the Building Now” Strategy

Buyers are frequently presented with an attractive base building price and urged to secure it immediately to “lock in steel pricing.” When questions arise about insulation, customers are often told:

“Your project coordinator will review accessories with you after the order is placed.”

This quote suggests that insulation pricing will be consistent with the competitive building quote!

Step 2: The Post-Order Accessory List

After the deposit is paid, the buyer receives a list of accessories, many of which are critical for any steel structure, at “outrageous high prices”. By this point in the ordering process, the seller has more pricing power as the customer is financially and psychologically committed to the building purchase. Many buyers feel they must purchase the insulation directly from the building supplier to avoid delays or mistakes. Also, many consumers wonder whether they have the expertise to source out accessories. Given the points stated, many buy their accessories, including insulation, at these overpriced prices.

Best Practices for Metal Building Buyers

Price vinyl faced Insulation Before Ordering the Building

Always obtain a detailed vinyl-faced fiberglass insulation quote at the same time as the building proposal.

Looking for more? Metal Buildings & Metal Building Kits by MBOS.