Fiberglass Insulation

Vinyl-faced fiberglass insulation | White Vinyl Face Insulation

See the wholesale price for vinyl-faced fiberglass insulation. Then, determine the profit for black or white vinyl face insulation.

Spirit has guided FSO to reveal the actual wholesale cost!

May it guide you to determine a “fair” profit (tip) and to pay it today!

Reinforced Vinyl-faced Fiberglass Insulation

To order, select the desired reinforced vinyl-faced fiberglass insulation by clicking the red “Buy Now” button below.

WMP-VR-R

Normal Strength

PSP-Polypropylene /Scrim/Polyester

Perm – 0.02

MD tensile lbs/inch – 35, XD – 35

Mullen Burst PSI – 100

Fire Performance: UL-723, ASTM E84, Factory Mutual, Class A-1

Featuring a tri-directional scrim.

The metalized polyester back reflects some radiant heat away from the structure.

This WMP-VR-R (plus) facing is easier to roll, cut, and install for DIY projects.

Most popular option!

WMP-10

Enhanced Strength

PSK-STD –Polypropylene/Scrim/Kraft

Perm 0.02

MD tensile lbs/inch – 40, XD – 35

Mullen Burst PSI – 65

Fire Performance: UL-723, ASTM E84, CAN ULC-S102M, Factory Mutual, BS 476 Class 0, Class A-1

The kraft side of WMP-10 & 30 may wrinkle less noticeably or recover more nicely over time than the metallized polyester of the WMP-VR (plus) and WMP-50.

WMP-30

Industrial Strength

PSK-HD Polypropylene/Scrim/Kraft Heavy Duty

MD tensile lbs/inch – 55, XD – 40

Mullen Burst PSI – 70

Fire Performance: UL-723, ASTM E84, CAN ULC-S102M, Factory Mutual, Class A-1

WMP-30 facing is often selected when the insulation may be exposed to additional wear and tear.

The WMP-30 is thicker and stiffer than the WMP-10; therefore, in tight or complex installations, it can be harder to work with.

WMP-50

Premium Strength

PSKP Polypropylene/Scrim/Kraft/Polyester

Perm – 0.02

MD tensile lbs/inch – 65, XD – 60

Mullen Burst PSI – 120

Fire Performance: UL-723, ASTM E84, CAN ULC-S102M, Factory Mutual, BS 476 Class 0, Class A-1

WMP-50 vinyl-faced insulation is the ideal choice for high-abuse areas that require extra durability.

The metalized polyester back allows it to reflect some radiant heat away from the structure.

The WMP-50 is thicker and stiffer than the WMP-30; therefore, in tight or complex installations, it can be harder to work with.

Vapor Barrier Protection Features

| Facing | Breathability | Vapor Control | Typical Use |

|---|---|---|---|

| WMP-10 | High | Low | Dry climates – low humidity |

| WMP-30 | Medium | Medium | Light-to-moderate humidity, mixed climates |

| WMP-50 | Low | High | Cold climates – moderate humidity |

| WMP-VR / VR Plus (Most popular) | Very low | Very high | High humidity |

Need Help Learning Your Building’s Square Footage?

Black faced Vinyl Faced Insulation.

WMP-VR-R (plus), WMP-10, and WMP-50 facing.

Silver-Reinforced Facing – High Flame Resistance

Our Silver-Reinforced facing faces the conditioned space (inside), just like Vinyl-faced insulation. Made in the same sizes/widths as VR-R (plus), so would have the same tab configuration options. It is used for higher flame resistance. Price is 7% higher than WMP-VR-R (plus).

Standard Roll Dimensions

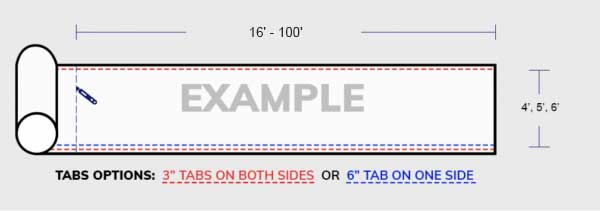

Standard Widths: 4′, 5′, and 6′. Length: 16′-100′. Standard Tabs: 2-3″. If you want 1-6″, please let us know. There is no additional charge.

- Custom Widths: 2′ width, tabs will be 2-9″. For 3’width, 2-3″ tabs. There will be an added cut charge equivalent to approximately 1′ of wider insulation.

- Custom Width: 8′ width is available only with the WMP-30. There is an additional $0.04 per sq. ft above the listed WMP-30 posted pricing. It will have 2-5″ tabs.

Please help reduce operational costs by letting the representative know your Wholesale Price and the profit amount when you call 1-888-512-1116.

Tape and Banding for Vinyl faced Fiberglass Insulation

Tape, banding, and screws will match the color of the chosen insulation facing. List desired items on the order form.

Same-Day Call Commitment Rewards

When you move forward on the same day as your consultation (profit secured by 12:00 a.m.), Factory Steel Overstock unlocks the following priority benefits as a courtesy:

🚚 Priority Shipping

Your order is upgraded to expedited delivery, arriving in 3–10 days rather than the typical 11–21-day timeframe.

💰 Distance-Based Freight Reduction

We analyze your exact proximity to the nearest manufacturing plant to identify $25–$100 in additional freight savings.

Returning Customer Advantage Program

To thank you for choosing FSO again, we extend enhanced benefits reserved exclusively for repeat customers:

💰 Recalculated Freight Savings

Your shipping distance is reassessed on every reorder to capture $25–$100 in additional cost reductions.

📉 Locked-In Low Profit Structure

Returning buyers qualify for a permanently reduced profit rate, positioned well below standard market pricing.

🚚 Accelerated Fulfillment

Orders receive complimentary expedited delivery in 3–13 days, compared to standard 14–21 days.

🏭 Plant-Direct Pickup Option

Access 24 insulation manufacturing facilities nationwide for no-cost pickup, eliminating freight altogether.

☎️ Direct, Human Support

Get real-time assistance 24/7 by phone, text, or email—no automated systems, no waiting.

All insulation types have their market niche, as well as pros and cons. Factory Steel Overstock could offer every insulation type; however, it to offers what the most cost-effective insulation for metal buildings and pole barns, which in fiberglass vinyl faced insulation.

Fiberglass Vinyl faced Insulation vs Spray Foam

COST:

One of the most expensive insulation options on the market is Spray foam. Unlike fiberglass, which is a popular DIY material due to its ease of installation, spray foam is far more labor-intensive and usually requires professional application. With a metal building, a layman simply rolls the vinyl-faced insulation over the purlins and girts, then pins it down while installing the sheeting material. Although Spray Foam may offer a higher per square foot thermal efficiency than fiberglass viny faced, one has to consider the additional initial investment required.

HEALTH FACTORS:

One must also consider that the chemicals used in spray foam can release toxic gases if not installed properly. That is not an issue with fiberglass vinyl-faced insulation. It is imperative that one verifies that the space being insulated is well-ventilated and that all safety measures are implemented during installation.

EXPANSION:

Fiberglass Vinyl-faced insulation is not going to expand; however, the nature of spray foam is to expand as it cures. This can sometimes lead to unwanted pressure on drywall and framing if not closely watched during installation.

Fiberglass Vinyl-faced Insulation vs Reflective

Effectiveness in Cold Climates

Reflective insulation is designed to reflect radiant heat away from your metal building or pole barn; therefore, it is an ideal insulation type in hot climates. Its primary purpose is to keep your structure cool; however, most locations require insulation to address climate conditions for all seasons. In other words, an insulation that also deals with winter temperatures. Reflective insulation has a limited ability to resist heat flow, which makes it less effective in cold climates. For this reason, fiberglass vinyl-faced insulation is a more practical choice.

Airspace Installation Requirements

Simply put, reflective insulation requires a gap to be effective, and there are situations where this may be a challenge during installation. This is not a requirement with Fiberglass Vinyl-faced insulation.

Although all insulation types have their market niche, pros and cons, fiberglass vinyl-faced insulation is the most preferred type for DIY projects. Ready buyers, call 1-888-512-1116.

I-Beam Metal Building

Podcast on Buying Buildings the Smart Way!

An Elderly Woman inspired our Insulation Selling Approach.

When I was a child, there was an elderly woman in our neighborhood who never opened her door on Halloween. Instead, she left a bowl of candy outside her door with a handwritten sign: “Please take only two pieces.”

Although I felt tempted, my two brothers and I always obeyed. We understood—intuitively—that the candy wasn’t just for us. It was our responsibility to leave some for the children who came after.

Years later, as I prepared to take my kids trick-or-treating, I realized no one would be home to hand out candy. So, I did exactly what that “elderly woman” had done many years earlier: I left a large bowl of candy outside the door with a sign that read, “Please take only two pieces.”

As my kids and I walked down the driveway to start trick-or-treating, a group of children rushed past us toward my front door. Then I heard someone exclaim, “Someone left all this candy!” Quite concerned about their intentions, I hurried back to my porch and saw them grabbing handfuls.

I asked, admittedly with some irritation, “Why didn’t you follow the instructions to take only two pieces?” No one answered; however, one young girl quietly returned some candy. The others ignored me and left with what they had taken. When my kids and I returned later that evening, I was pleasantly surprised to see some candy still left in the bowl, which reassured me that there are still those who do the right thing when no one is looking!

Fast-forward to today: Instead of leaving candy outside the door and asking for you to take two pieces, we’re presenting you with the “actual” wholesale price for insulation.

The instructions are still clear:

Leave a “fair” profit.

Read 90 more testimonials or click the BBB logo to see our report.

.

Looking for more? Metal Buildings & Metal Building Kits by MBOS.